Find the best fit for your network needs

share:

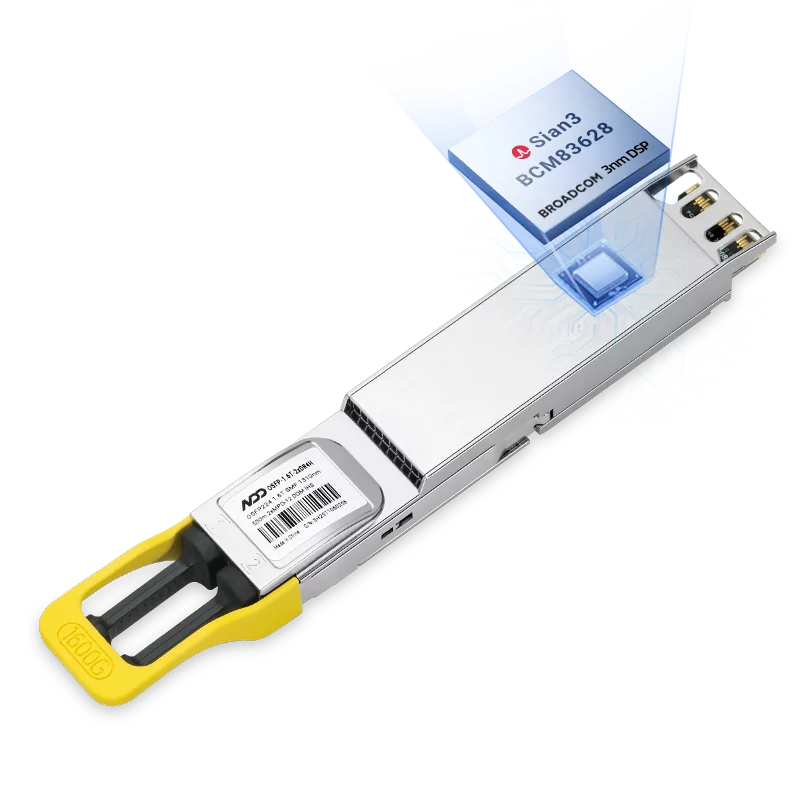

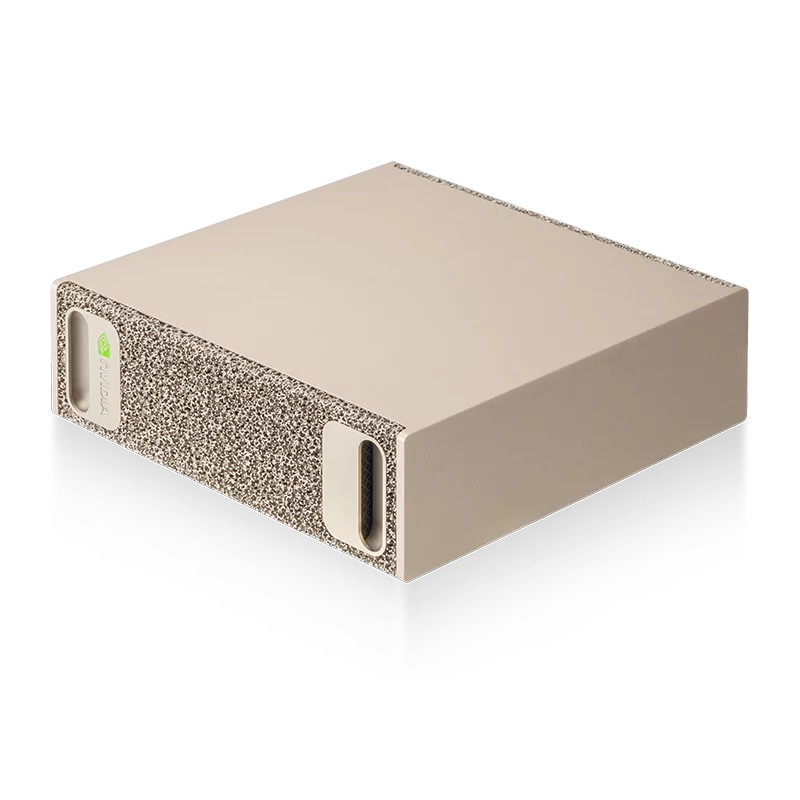

800GBASE-2xSR4 OSFP PAM4 850nm 50m MMF Module

800GBASE-2xSR4 OSFP PAM4 850nm 50m MMF ModuleLearn More

Popular

- 1Building and Optimizing Large-Scale GPU Clusters: Insights and Innovations

- 2In-Depth Look at NADDOD's OSFP 800G DR8 and 400G DR4 InfiniBand NDR Transceivers

- 3The Latest Trends in Backbone Network Optical Communications

- 4The Key Role of High-quality Optical Transceivers in AI Networks

- 5Common Problems While Using Optical Transceivers in AI Clusters